Tshuab Taw Qhia

Cov qauv ntawm lub tshuab yog muaj zog thiab ruaj khov, ntau lub luag haujlwm thiab yooj yim rau kev khiav lag luam.Lub tshuab ua haujlwm kev ua tau zoo yog ruaj khov nrog cov neeg siab.siab automation degree, siab raug thiab kev ntseeg tau, kev lag luam tus nqi, yooj yim rau kev khiav lag luam thiab tswj, thiab lwm yam.

tuaj yeem txiav cov duab dav hlau.

Txiav roughness tuaj yeem ncav cuag 25 (▽3), Tom qab txiav, qhov saum npoo tsis tas yuav tsum tau ua.

Nrog lub siab automation, yooj yim rau siv, siab precision, siab ntseeg tau thiab tus nqi qis.

Kev ua haujlwm yooj yim, txij nkawm, thiab lwm yam,

Lub tshuab no yog siv dav hauv tshuab fabrication.Tsev Vessel .pressure nkoj.engineering tshuab.mining tshuab.Hluav taws xob.kev tsim kho choj.steel qauv thiab lwm yam. Nws yog tsuas yog siv rau cov ntawv hlau txiav.

Basic configurations thiab technical parameters

1. Siv cov lus qhia kom meej meej, dual tsav.Lub tshuab ua haujlwm noiselessly nrog kev kub ceev thiab siab precision.

2. Human-computer interface tsim ua rau lub tshuab yooj yim kawm thiab ua haujlwm, thiab muaj kev ua tiav.

3. Muaj 10.4 nti xim LCD zaub thiab ua haujlwm vaj huam sib luag, thiab nyeem cov kev pab cuam thiab software upgrade los ntawm USB flash tsav.

4. Muaj kev ua haujlwm ntawm kev nco thiab rov ua haujlwm thaum lub hwj chim tawm.

5. Muaj lub luag haujlwm ntawm wireless chaw taws teeb tswj uas tuaj yeem tswj kev txiav ntawm txhua qhov chaw nyob ib puag ncig lub rooj tswj hwm.

6. tuaj yeem xaiv qhov tsis siv neeg arc voltage torch qhov siab tswj lossis hluav taws xob qhov siab.

7. tuaj yeem zam kev cuam tshuam ntau zaus thiab ua rau txiav kom ruaj khov thiab nyab xeeb.

8. Txiav taws tuaj yeem ua raws li cov neeg siv khoom xav tau los nruab nrog cov ntshav lossis cov nplaim taws

9. Kauj ruam lub cev muaj zog, ob tog tsav

10. Nrog tshuab, yuav standardly equip FASTCAM nesting software, nplaim taws txiav nozzle.Plasma nozzle.Transmission U flash.Lub tshuab ua haujlwm CD.

| Txiav hom | Nplaim txiav + plasma txiav |

| Cov ntaub ntawv txiav | Carbon steel, stainless hlau, aluminium, thiab lwm yam |

| Nplaim txiav thickness | 8-200 hli |

| Plasma txiav thickness | 0.4-30mm nyob ntawm lub zog plasma |

| Standard txiav ntau yam | 3000mm × 6000mm (Kev xaiv 3000 * 8000 / 4000 * 6000 / 4000 * 8000mm, lwm qhov loj tuaj yeem kho tau) |

| Vertical stroke ntawm txiav taws | 150mm (200 Thiab siab dua yog xaiv tau) |

| Tswj qhov system | Fangling F2100B / Starfire Controller / Pib Controller |

| THC | Tsis siv neeg txiav qhov siab maub los |

| Cov lus ua haujlwm | Lus Askiv, Fabkis, Lavxias, Spanish, thiab lwm yam |

| Software | Fastcam, Starcam, thiab lwm yam |

| Tsav Tsheb | Stepper Tsav Thiab Tsav Tsheb (Servp motor yog xaiv tau) |

| Max.Txiav ceev | 12000mm / Min (kev teeb tsa sib txawv thiab cov khoom sib txawv thiab thickness ceev sib txawv) |

| Max.Taug kev Ceev | 30000mm / Min (sib txawv configuration ceev yog txawv) |

| Ua hauj lwm voltage | 380V / 3ph (220V / 3ph yog xaiv tau) |

| Plasma Generator | Huayuan Tuam Tshoj thiab Asmeskas lub zog raws li koj xav tau |

| Tso zis tam sim no | 63/100/120A/160A/200A Tuam Tshoj (45/65/85/105/125/200A USA) |

| Khoom siv ua haujlwm | Hlau, Aluminium, Galvanized Sheet, Titanium Phaj, Platinum Phaj thiab yuav luag tag nrho cov hlau |

Machine Performance thiab nta

1. Tsim nyog cov qauv tsim, Tag Nrho Optocoupler Isolation Control thiab Super tiv thaiv kev cuam tshuam muaj peev xwm ntawm plasma;

2. Ib qho kev pab cuam lub cim xeeb muaj zog, kom tau raws li ntau yam kev ua haujlwm nyuaj ua haujlwm thiab ua haujlwm thiab tswj cov haujlwm loj khiav tau yooj yim;

3. Cov duab duab .Display cov npe, yooj yim rau cov neeg siv txheeb xyuas cov ntsiab lus ntawm cov ntaub ntawv ncaj qha;

4. Siv U-disk hloov CAD graphic cov ntaub ntawv rau trajectory input;

5. Cov txheej txheem ua haujlwm tuaj yeem hloov tau txhua lub sijhawm;

6. Cov kauj ruam tsav lub cev muaj zog, siv lub siab tawg, nrog kev ua haujlwm siab thiab ua haujlwm zoo;

7. Ncua sijhawm, preheating, perforated, nruam rov qab, breakpoint rov qab;

8. Ceev tuaj yeem hloov kho arbitrarily;

9. Nruab nrog lub teeb pom kev ua haujlwm;

10. Humanized lag luam interface, Daim Ntawv Qhia Lus Askiv puv thiab siv tau yooj yim;

11. CRC ntse Calibration thiab kev sim uas ua rau cov ntaub ntawv tsis tsuas yog kev ruaj ntseg thiab txhim khu kev qha, tab sis kuj los tiv thaiv cov ntaub ntawv yuam kev tsim.

12. Kho vajtse tsis ua haujlwm yuav raug kuaj xyuas thiab xa daim ntawv tshaj tawm tau txais thaum pib lub tshuab.

1. Yooj yim kawm, yooj yim Interface

CAD cov duab los ntawm kev hloov software los tsim txoj hauv kev txiav, txiav tawm sab hauv thiab sab nraud txiav, Tsis siv neeg tsim cov hlau lead hauv thiab tawm kab.Tsim nyog rov ua dua tshiab, lub qhov sab hauv yog nyiam.Ib qho khoom siv ntxiv yog nyiam, tuaj yeem siv.

Ib daim duab tsis kaw rau kev txiav tshwj xeeb.Ntev daim ntawv txiav, txo cov cua sov deformation efficiency.Muaj peev xwm muab tau hom 3, Mastercam, ProE, CAXA, artcut.etc.software rau connector.

Kerf tau txais kev them nyiaj, kev sib koom ua ke nesting, tsis siv neeg sorting, nruam bulk txiav. Tsis siv neeg nce thiab qis qis, tsis siv neeg txiav pib taw tes, kaum ceev yog ruaj khov, txhim kho kev txiav raug.

Sab hauv thiab sab nraud teeb U flash txoj kev, hloov cov ntaub ntawv los ntawm sab nraud U flash mus rau sab hauv U flash.Txawm tias hluav taws xob fais fab tuag, cov ntaub ntawv yuav tsis poob.Para khaws cia los ntawm txoj kev ntawm compression code, txhim kho lub khw zoo.Nrog tshuab los teeb encrypt.Xyuas kom cov ntaub ntawv muaj kev nyab xeeb.

2.Kev khiav hauj lwm yog yooj yim, txij nkawm yog yooj yim

Tus phooj ywg interface, Suav thiab lus Askiv zaub, nrog lub tshuab ua haujlwm txoj hauv kev, keyboard yooj yim, ua haujlwm nrawm, meej meej ntawm ib nrais muag.Interface teeb tuaj yeem muab kev kuaj xyuas yuam kev.

3.Inexpensive thiab compact qauv

Qhov chaw tsim nyog-txuag kev npaj thiab muaj zog compact tsim ua rau lub tshuab khiav zoo dua thiab txiav kev ruaj ntseg zoo.

4. Ua kom muaj kev tiv thaiv jamming thiab zam qhov tsis ua haujlwm feem ntau

5. Cov duab kos duab

6. Fais fab tuag nco

Mechanical qhov tseem ceeb

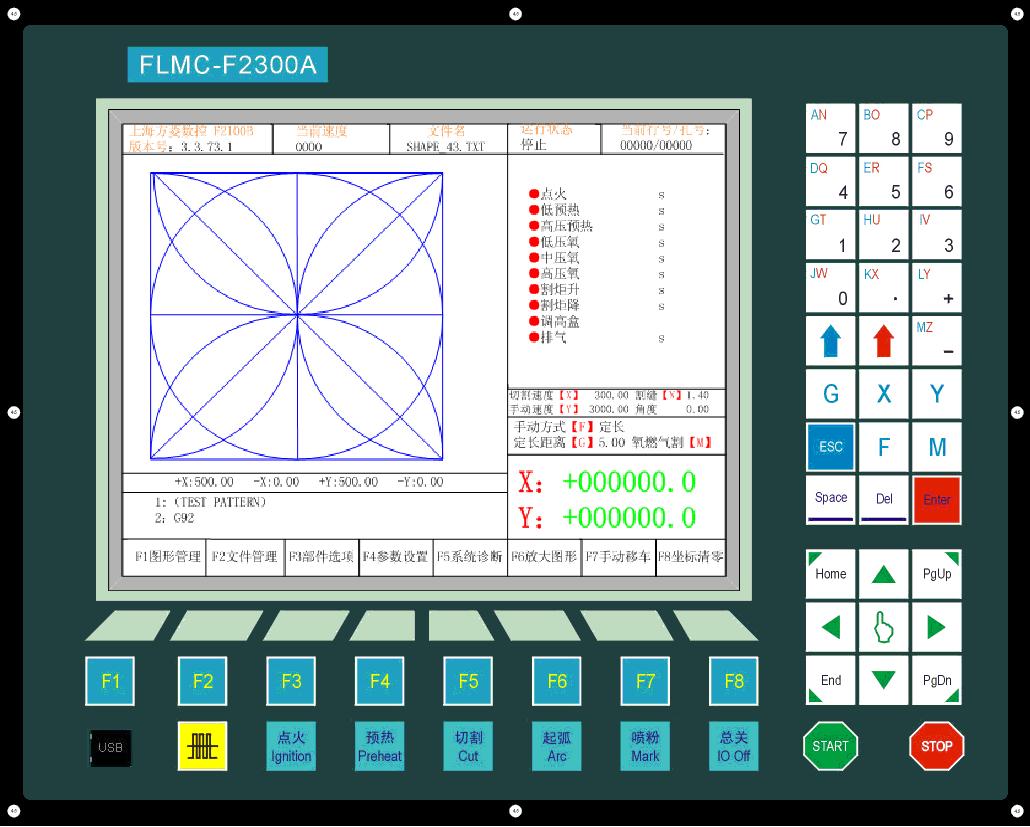

CNC system qhia

1. Cov kab ke no tau tshawb fawb los ntawm Shanghai jiaotong tsev kawm ntawv txiav tshuab nrog ob axis digital controller, nws tsim nyog rau cov pa oxygen thiab ntshav txiav kev lag luam.Tag nrho cov kev khiav hauj lwm muaj cov ntawv qhia zaub mov thiab cov lus qhia, Cov haujlwm zoo meej, ua haujlwm yooj yim, siv tau yooj yim.Qhov system txais kev kub ceev ARM9 thiab DSP tswj cov qauv, ua cov txheej txheem txiav ntau ruaj khov thiab txhim khu kev qha.

Main Cav Dub 10.4" Zaub Vaj Huam Sib Luag

Daim duab 1 MINI-CNC

2. System Configurations:

● Zaub: 10.4 "800 * 480 siab daws teeb meem 16 lab xim siab brightness LCD npo

● CPU: 64M SDRAM

● Internal cia: 256MB

● Qhov tseem ceeb zaus: 400 MHZ system zaus

● USB: USB1.1 interface pem hauv ntej, yam tsawg kawg txhawb 16 gb USB flash drive

● Keyboard: cov keyboard PCB lamination

● Case: tag nrho cov qauv steel tag nrho shielding, tiag tiag tuaj yeem tiv thaiv hluav taws xob hluav taws xob, tiv thaiv kev cuam tshuam.

3. Txheej Txheem;

● Suav, Lus Askiv, Kaus Lim Kauslim, Portuguese, Fabkis, Lavxias, Denmark thiab lwm yam lus, ib-nias hloov.

● 47 hom kev siv cov duab kos duab (nrog rau cov qauv kab sib chaws), tuaj yeem xaiv cov ntawv loj thiab qhov loj;

● Txhawb EIA code (G code) thiab FastCAM, FreeNest, SmartNest, IBE thiab lwm yam. nesting software;Graphic scale, rotation, daim iav, matrix arrangement;

● Compact hom keyboard tsim, ua kom paub ntau ntxiv phau ntawv input ntaub ntawv;

● Duab nplai, kev sib hloov, daim iav;

● Matrix kev npaj, sib tham sib graphics tuaj yeem npaj, fold hom kev npaj;

● Graphic phaj kho, arbitrary phaj ntug yuav ua tau raws li kev kho;

● Customizable coordinate system, txhawb 2 d coordinates ntawm tag nrho yim muaj peev xwm;

● Customizable txhua hom input thiab output chaw nres nkoj (ib txwm qhib los yog ib txwm kaw) thiab serial tooj;

● Muaj peev xwm kuaj tus kheej qhov chaw nres tsheb IO thiab lub xeev tseem ceeb, yooj yim rau kev kuaj xyuas thiab daws teeb meem;

● pem hauv ntej usb interface, yooj yim thauj kev pab cuam;

● Oxygen gas thiab ntshav IO tswj cais;

● Cov pa roj tuaj yeem hloov tau qhov siab thiab ob theem ntawm preheating, qib 3 perforation;

● Plasma arc voltage tawm tswv yim, txoj hauj lwm tawm tswv yim, ces kaum kaw Plasma arc voltage, kom tsis txhob kov teeb;

4. Cov ntaub ntawv txheej txheem

● Tswj cov lej: 2axies txuas (tuaj yeem kho tau rau 3 axies)

● Tswj qhov tseeb: ± 0.001mm

● Coordinate ntau yam: ± 99999.99mm

● Qhov siab tshaj plaws mem tes zaus: 200KHz; Qhov siab tshaj plaws ceev: 15m / feeb

● Cov kab ntau tshaj plaws: 150,000lines;

● Qhov max.ib program: 6MB

● lub sij hawm daws teeb meem: 10ms

● Lub cev ua haujlwm lub zog: DC + 24VDc lub zog nkag

● Lub kaw lus ua haujlwm ib puag ncig: kub-10 ℃ to + 60 ℃ ; txheeb ze av noo 0-95% Tsis muaj condensation

5. Qhov system interface

● 15 core thiab ob axis tsav tsav interface

● 25 core poj niam lub taub hau 16-txoj kev optoelectronic cais tawm, qhov siab tshaj plaws ntws rov qab 300mA

● 25 core poj niam lub taub hau 16-txoj kev optoelectronic cais tawm tswv yim, qhov max input hluav taws xob

● nyob rau pem hauv ntej vaj huam sib luag built-in USB interface, yooj yim rau cov neeg siv kis tus lej txiav.Nthuav IO input/output chaw nres nkoj;PWM input/output port; Analog input port; Coding input ports

Program Software

Qhov no yog tag nrho automated system nrog rau qib siab ntawm automation thiab tsom rau kev txuag lub sijhawm.Uas yog raws li daim duab AutoCAD.Lub software yooj yim kawm tau tuaj yeem hloov pauv AutoCAD daim duab int rau G-code cov ntaub ntawv, thiab tom qab ntawd hloov G-code cov ntaub ntawv rau hauv CNC txiav tshuab los ntawm USB yuam kev uas yooj yim rau kev khiav lag luam.

Plasma Power Source: Txhua hom

CNC txiav tshuab yog sib xws nrog txhua hom plasma.

CNC txiav tshuab feem ntau daws teeb meem thiab txij nkawm

1. Cov neeg ua haujlwm yuav tsum ua tib zoo nyeem CNC txiav tshuab cov lus qhia thiab kev siv.

2. Cov neeg ua haujlwm mloog thiab kawm txog lub Hoobkas engineer lub installation, kev cob qhia thiab kev sim.

3. Ua ntej txiav yuav tsum xyuas cov roj hluav taws xob hluav taws xob.txiav taws.thiab lwm yam kev sib txuas qhov chaw yog tias muaj qhov tshwm sim xau, ib zaug pom, yuav tsum tau txiav tawm.

4. Yuav tsum tau ua tib zoo xyuas seb tus naj npawb ntawm lub nozzle puas sib haum nrog cov roj txiav thiab txiav steel phaj thickness, tsis tuaj yeem siv dhau ntawm qhov txiav nozzle siv ntau yam.

5. Tshawb xyuas seb txhua yam roj av siab puas nyob rau hauv daim ntawv tso cai.

6. Tshawb xyuas lub tshuab ua hauj lwm phau ntawv qhia seb puas meej, khib puas puas.

7. Cov pa oxygen txwv tsis pub sib cuag nrog cov khoom siv roj thiab cov khoom siv (xws li cov khaub ncaws, paj rwb, thiab lwm yam), Yog tias muaj hluav taws kub sib tsoo.

8. Thaum lub tshuab ua haujlwm, cov neeg ua haujlwm yuav tsum kuaj xyuas lub zog hluav taws xob hauv lub sijhawm, tshem tawm tag nrho lub tshuab tawm ntawm cov teeb meem hauv cheeb tsam ua haujlwm.

9. Thaum lub tshuab muaj suab nrov, nws yog tshwm sim los ntawm Transmission clearance, Yuav tsum tau kho kom tshem tawm.

10. Thaum lub tshuab tsis ua haujlwm, nws yuav tsum nres nyob rau hauv txoj haujlwm qhib, Z axis thiab lub teeb hluav taws xob nres, nres lub txee tswj sab.

11. Thaum lub tshuab tsis ua haujlwm thaum khiav, nres tam sim ntawd, Chaw nres tsheb mus rau qhov chaw nyob hauv lub sijhawm, nws yooj yim rau kev saib xyuas thiab kuaj.

12. Thaum tus neeg teb xov tooj so lossis tawm lub tshuab rau lub sijhawm ntev, peb yuav tsum tua lub hwj chim thiab cua.

13. Tshuab longitudinal qhia rails thiab kab rov tav qhia rail lub nto tom qab siv yuav tsum so thiab daub ntawm lubricating roj kom plua plav tsis xeb.

14. Lub tshuab txiav tom qab siv yuav tsum tau muab tso rau hauv txawm tias qhov seem ntawm cov pa (kaw tawm cov pa oxygen thiab acetylene gas qhov chaw, lub raj roj tuaj yeem tawm).

15. Ua ntej yuav tawm haujlwm yuav tsum tua tag nrho cov pneumatic system.

16. Txhua lub lis piam nws yuav tsum tau kuaj xyuas hluav taws xob thiab roj hluav taws xob, txhua lub hlis siv txhuam txhuam los ntxuav cov plua plav ntawm lub tshuab sab, thiab qhib lub tshuab txee los ntxuav lub tshuab sab hauv thiab txhua lub tshuab hluav taws xob cov plua plav.

17. Yog xav paub ntxiv txog kev paub txog kev tu tshuab, thov mus saib peb lub vev xaib www.cncam.net, peb lub tuam txhab yuav tsis hloov kho cov khoom thiab cov txheej txheem kev ua haujlwm tsis tu ncua.

Kev daws teeb meem ntawm qhov system

Raws li qhov system configurations thiab txhua qhov kev ua haujlwm, qhov system tsis ua haujlwm tuaj yeem muab faib ua qhov tseem ceeb tswj tsis tau.U flash kev twb kev txuas tsis ua hauj lwm.Lub cev muaj zog tsav tsis ua haujlwm.Hluav taws xob valve tsis ua haujlwm.Ignition system tsis ua hauj lwm.Mechanical system tsis ua hauj lwm .etc.Tsuas yog Mechanical system, lwm qhov chaw tuaj yeem raug xa mus rau cov roj hluav taws xob tsis raug.

1. Mechanical system faults

Mechanical qhov chaw tus qauv yog yooj yim, thiab yuav luag tsis muaj faults tshwm sim, thiab faults yog pom tseeb, rau ib txwm cov neeg siv yuav tsis muaj teeb meem.Tab sis ntawm no yuav tsum stressed:

Thaum lub tshuab muaj suab nrov, nws yog tshwm sim los ntawm Transmission clearance, Yuav tsum tau kho kom tshem tawm.

2. Kev daws teeb meem hluav taws xob

System hluav taws xob ntau faults thiab daws nrog txoj kev:

| Ua txhaum | Faults ua rau | Txheeb xyuas cov kauj ruam thiab kev tshem tawm |

| Thaum pib lub tshuab, lub teeb ntawm Switch tsis ci | Sab nraud 220v fais fab tuag tsis muab hluav taws xob ua kom raug | 1. Sab nraud qhov (socket) tiv tau zoo, yog tias muaj hluav taws xob ntawm lub qhov (socket). 2. Unscrew lub txee vaj huam sib luag ntawm kev tuav pov hwm header, xyuas seb puas muaj kev pov hwm lub raj puas (kev pov hwm rau 3 a); 3. Qhib lub qhov rooj txee, xyuas seb qhov chaw txuas hluav taws xob puas poob tawm qhov tshwm sim. |

| Thaum pib lub tshuab, txawm tias LCD muaj cov zaub lossis tsis | 1.main tswj board muaj faults 2.plug hu tau zoo los tsis | 1.Qhib lub vaj huam sib luag, Los ntawm qhov taw qhia ntawm lub rooj tsav xwm tseem ceeb los txiav txim yog tias muaj lub hwj chim; 2.Mainly mus xyuas connectors yog tso los yog tsis 3.hloov lub ntsiab tswj board. |

| txhua qhov hluav taws xob valve tsis ua haujlwm | Hauv tshuab tsis muaj lub zog + 24V | Los ntawm lub rooj tsav xwm tseem ceeb + 24V lub teeb hluav taws xob tuaj yeem txiav txim siab seb puas muaj +24V fais fab lossis tsis |

| tshuab ob leeg hauv X thiab Y tsis tuaj yeem txav tau | main control board tsis muaj teeb liab tso zis tsis muaj kauj ruam tsav tsav lub zog | Ua haujlwm yuam sij kom txav tshuab, saib xyuas lub rooj tsav xwm tswj lub ntsiab lus qhia lub teeb, tuaj yeem txiav txim siab qhov tsis raug tshwm sim txawm tias nyob rau hauv lub rooj tsav xwm loj lossis tsis. Siv lub ntsuas hluav taws xob los kuaj xyuas lub cev muaj zog seb puas muaj hluav taws xob lossis tsis muaj |

| qee qhov hluav taws xob valve tsis tuaj yeem ua haujlwm | 1.cuam tshuam los yog tsav tsheb puas 2. kev hu tsis zoo 3. hluav taws xob valve puas lawm | 1. Rau hauv cov pa taws hluav taws xob txiav, ua txhua lub valve rau hauv chaw ua haujlwm, qhib lub txee, los ntawm kev txiav cov txee lub teeb qhia, tuaj yeem txiav txim siab seb puas muaj cov lus tswj hwm 2. Ntawm Lub Rooj Tswjhwm Saib Xyuas muaj cov tsav hluav taws xob sib raug zoo, hauv "kev sim hluav taws" lossis "txiav" saib lub rooj tsav xwm tswj lub ntsiab lus qhia lub teeb ci los yog tsis, thiab ua tib zoo mloog seb puas muaj hluav taws xob valve ua suab, thiab txiav txim siab qhov txhaum. |

| Tshuab nyob rau hauv X thiab Y kev taw qhia muaj ib qho kev taw qhia txav tsis tau | 1. ntawm lub rooj tsavxwm tswj tsis muaj lub zog tswj lub teeb liab 2.coj tsav muaj faults | 1. siv txav chaw ua haujlwm txav lub tshuab, los ntawm qhov taw qhia lub teeb kom saib xyuas lub rooj tsav xwm tseem ceeb seb puas muaj cov teeb liab sib cuam tshuam 2. Los ntawm kev tswj lub txee tshem tawm lub cev muaj zog, saib xyuas lub cev muaj zog seb puas muaj kev sib kis lossis tsis tau |

Kev pabcuam thiab kev cog lus zoo

1. Lub tshuab muaj 14 lub hlis txwv kev lav zoo.

2. Peb txoj cai zoo: Nrog cov khoom txaus siab .kev pabcuam siab dawb, zoo tshaj plaws kom tau raws li cov neeg siv khoom xav tau. "

3. Lub tuam txhab muaj zoo meej ua ntej muag.Muag.Kev pab cuam tom qab muag.Kuj muab kev saib xyuas.kho kev pabcuam txawm hais tias nws dhau lub sijhawm lav (tsuas yog them tus nqi sib xws)

4. Peb yuav muab kev sov so.Kev pabcuam raug thiab raws sijhawm, sim peb qhov zoo tshaj plaws kom tau raws li koj qhov kev cia siab thiab kev xav tau.thov hu rau peb raws sijhawm.

-

Ua haujlwm zoo loj 1500 * 3000mm me plasma ...

-

Sab saum toj Zoo Txiav Loj Daim Ntawv Kub Muag Pla...

-

High Accuracy 5 Axis Siab Tsis Siv Neeg cnc yeeb nkab c ...

-

High Productivity Plasma Txiav Qhov Zoo Tshaj Plaws Cnc ...

-

2022 Kub Muag Newest Heavy Rail Gantry Hom CNC ...

-

Gantry hom ntau strip gas txiav tshuab ...