1. cnc ntshav txiav tshuab piav qhia

Luv luv Taw qhia ntawm cnc plasma txiav tshuab

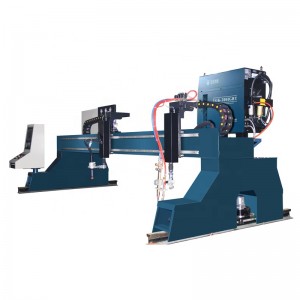

YM-CS GCNC ntshav plasmathiab nplaim tawstxiav tshuab yogahom high-efficiency steel phaj tsis siv neeg txiav cov cuab yeej tsim los ntawm peb lub tuam txhab rau ntau yam duab ntawm cov ntawv hlau.cnc plasma txiav tshuab nqeadopts gantry qauv hom, ob tog tsav tsheb thiab iav khib.cnc plasma tej tshuab nqe muajcov yam ntxwv zoo rigidity, kev kub ceev, hollow lub thawv tsim thiab zoo tshav kub dissipation;cnc plasma txiav tshuab nqetuaj yeem txiav longitudinally thiab horizontally, thiab tseem tuaj yeem txiav rau txhua qhov kev taw qhia ntawm arc nkhaus, nrog kev txiav qhov siab thiab qhov tseeb, thiab me me deformation;txais yuav ob qho tib si ntsug thiab kab rov tav cov lus qhia Imported high-precision reducer txhim kho lub tshuab khiav qhov tseeb ntawm txhua qhov txuas.cnc plasma txiav tshuab nqemuaj lub backlash-dawb gearing kis tau tus mob hom, uas yuav khiav dexterously thiab smoothly ntawm kev kub ceev thiab muaj siab txiav precision.Lub iav khib tau txais tshwj xeeb iav khib rau cov cuab yeej siv tshuab, uas muaj peev xwm loj thiab muaj kev sib kis tau zoo.cnc plasma txiav tshuab nqe tseem muaj kev sib tw hauv kev ua lag luam.

2. cnc plasma txiav tshuab nqe zoo vim yog BasicMachine Configurations

Mechanical ib feem

| 1 | Tshuab dav | 4000 hli |

| 2 | Longitudinal rail ntev | 10000 hli |

| 3 | CNC plasma txiav teeb | 1set ib |

| 4 | THC | 1set ib |

| 5 | Nplaim taws | 1set ib |

| 6 | Tsis siv neeg ignition ntaus ntawv | 1set ib |

| 7 | Txiav taws lifting lub cev | 2 teeb |

| 8 | Tsav txoj kev | Servo ob tog tsav |

| 9 | Txoj kev xa cov kav dej | Kab rov tav cab saw, ntsug cab saw |

| 10 | Central gas sib sau ua ke tswj system | 1set ib |

| 11 | System, console kev taw qhia | Tshwj xeeb raws li cov neeg siv khoom xav tau |

| 12 | Tus neeg yuav khoom yog lub luag haujlwm rau cov khoom no | Kev tsim kho ntawm kev txiav platform, hnyav beam ntau lawm, cement foundation ntawm qhov chaw teeb tsa, kev sib kis ntawm cov kav dej ntev thiab lwm yam haujlwm yooj yim yuav raug ntsia los ntawm tus neeg yuav khoom, thiab tus neeg muag khoom yuav muab kev taw qhia kos duab. |

Electronic tswj ib feem

| 1 | CNCTus tswj | Shanghai Jiaotong University F2300B |

| 2 | Plasma zogqhov chaw | Raws li koj xav tau |

| 3 | Nplaim taws | Wuxi Longteng |

| 4 | Tsav system / lub cev muaj zog | Panasonic |

| 5 | Reducer | Pib tshiab |

| 6 | Tsis siv neeg programming, nesting software | Starcam |

3.TshuabWorkingCkev xav

| 1 | Hwj chimqhov chaw voltage / zaus | Peb theem 380v±10% / 50HzIb theem 220v±10% / 50Hz |

| 2 | Input zog | 3 KW |

| 3 | Compressed cua | Qhuav thiab tsis muaj roj;Siab: 0.8Mpa Flow: 1.0 m3 / h |

| 4 | Gas hom | Propane\acetylene\propylene\natural gas. |

| 5 | Ambient kub | 0-50℃ |

| 6 | txheeb ze humidity | <90% tsis-condensing |

| 7 | Ib puag ncig | Qhov cua.Tsis muaj kev cuam tshuam loj hauv 5 meters |

| 8 | Av qeeg theem | Fortify ntawm qib rau |

4. cnc plasma txiav tshuab nqi yog muaj nqis vim yogCov ncauj lus kom ntxaws

| Lub npe | Pdaim duab | Cov lus qhia ntxaws |

| Tshuab ncej |

| 8mm tuab steel welded, muaj zog qauv (lwm lub tuam txhab feem ntau sivs6mm tuab steel) |

| Pem hauv ntejbua eam | | 20mm thickness pem hauv ntej beam, tom qab ib lub sij hawm loj gantry milling, nce qhov parallelism thiab positioning raug. |

| Hollow tsim |

| Nws txais kev tsim hollow, zoo cua sov dissipation, nce lub zog ntawm cov qauv, siv ntev tsis muaj deformation.Overall txhaj tshuaj blasting kom paub meejnqajzoo li zoo;Overall tshuaj tsuag kev kho mob, cua sov annealing, lavremoval ntawm vuam kev nyuaj siab; CNC milling kom ntseeg tau siab precision ntawm kev ua qhov ntev, kev co laus los tiv thaiv kev deformation;multi-pass spraying los xyuas kom meej txheej thickness thiab adhesion. Kev tshuaj xyuas zoo: kev tshuaj xyuas tshwj xeeb ntawm txhua tus txheej txheem |

| Ntevtsav tswj system

| | Tsav hom: ob togPanasonicservo driveTransmission hom: precision iav, khib, lub teb chaws tus qauv qhia rail thiab servo high-precisionpositioning kis tau tus mobGear khib: iav raug qib 6, khib module 2. Kev tiv thaiv kev ntsuas: Lub log eccentric clamping siv cov plua plav pov thawj thiab cov ntawv hlau npog los tiv thaiv cov khoom siv hluav taws xob los ntawm kev ua qias tuaj los ntawm plua plav. |

| Lateral tsav tswj system | | Tsav hom: Panasonic servo drive.Transmission hom: precision iav, khib, thiab servo high-precision positioning kis tau tus mob, uas muaj peev xwm ua tau zoo txav ntawm lubmain torch thiab sub torchdhausteel hlua drive ntaus ntawvLateral guide rail: high-precision single-axis core guide.Gear khib: iav raug qib 6, khib module 2. Kev sib txuas hom: iav khib meshing kev twb kev txuas. |

| Pneumatic kis tau tus mob hom | | Muaj ntau cov cables thiab cua qhov chaw nyob rau hauv longitudinal kev taw qhia, uas yuav cuam tshuam rau smoothness thiab kev ntseeg siab ntawm lub tshuab ua haujlwm.Lub luag haujlwm txuas ntxiv yog siv los ua kom huv si ntawm cov kav dej., Thiabitua taukujtxo qhov nyiam ntawm lub tshuab kom overshoot thaum khiav ntawm kev kub ceev.Nws tuaj yeem tiv thaiv cov raj xa dej los ntawm kev hnav los ntawm kev kub ceev txiav txav;nws tseem tuaj yeem txuag cov kav dej ntev. |

| Longitudinal rail | | Qhia rail specifications: lub teb chaws tus qauv hnyav 24Kglub 30 KgRail khoom: high-strength tshav kub-kho railGuide rail processing: Nws yog tsim los ntawm kev sib tsoo nrog high-precision qhia rail grinder kom lub siab precision thiab stability ntawm tej tshuab.Hnoj-kho hnyav-lub luag hauj lwm khib yog ntsia rau sab nraum ntawm kev qhia rail kom ntseeg tau siab precision thiab ntev lub neej ntawm cov kis tau tus mob |

| CNC txiav lub teeb txav lub cev | | Material: zoo txhuas phaj Txheej txheem txheej txheem: CNC drilling thiab millingAuxiliary Cheebtsam: koom tes los sib sau ua ke ntau yam CNC lifting lub cev, thiab lwm yam. |

| Tsis siv neeg ignition ntaus ntawv | | Ignition txoj kev: nruam mem tes tsis siv neeg hluav taws xob ignitionControl hom: phau ntawv tswj ntawm lub lag luam vaj huam sib luag, ntxiv cov lus txib tswj hauv programComponent nta: Lub neej kev pab cuam tau ntev heev, qib ntawm automation siab, kev siv zog ntawm cov neeg ua haujlwm raug txo, kev nyab xeeb yog txhim kho. , thiab qhov zoo ntawm ntau yam torches yog qhov tseem ceeb |

| Plasma txiavtawstiv thaiv kev sib tsoo | | 360 ° tiv thaiv kev sib tsoo mechanism yog tswj los ntawm sensor.Thaum lub plasma txiav taws raug ntaus rau txhua qhov kev taw qhia, lub tshuab tam sim ntawd nres. |

| CNCTus tswj | | Kev sib xyaw ua ke:cnc tswj lub thawv,cnc tus tswj, khawm tswj vaj huam sib luag, thiab lwm yam khoom siv hluav taws xob. |

| Hluav taws xob tswj lub thawv | | Cheebtsam: hluav taws xobtswjlub thawv,Panasonic servo drives, Schneider Electric Cheebtsam, thiab lwm yam. |

5. cnc plasma txiav tshuab nqe yog txiav txim siab los ntawm Technical Parameters

| 1 | Siv tau txiav dav | 3150 hli |

| 2 | Siv tau txiav ntev | 8000 hli |

| 3 | Nplaim txiav thickness | 6-150 hli |

| 4 | Plasma txiav thickness | ≤30mm |

| 5 | Txiav taws lifting nrug | 200 hli |

| 6 | Kev khiav hauj lwm ceev ntawm tag nrho lub tshuab | 0-9000mm / min |

| 7 | Kev teeb tsa ceev yuam kev | ≤ ± 5% |

| 8 | Tsis siv neeg kho siab precision | ≤ ± 1.0mm |

| 9 | Longitudinal ncaj kab raug | ± 0.3 hli |

| 10 | Zuag qhia tag nrho qhov tseeb ntawm tag nrho lub tshuab (Raws li cov duab zoo) sab ntev (plaub sab) 1000X1000 Scribing ceev 500-800mm / min | |

| 11 | Sab Length (plaub sab) | ± 0.5 hli |

| 12 | Diagonal yuam kev|AD-BC| | ± 0.5 hli |

| 13 | Rov qab mus rau keeb kwm sib txawv | ± 0.2 hli |

| 14 | Kev sib tshuam sib txawv | ± 0.5 hli |

| 15 | Forward thiab thim rov qab ncaj kab sib txawv | ± 0.2 hli |

| 16 | Txiav nto zoo (roughness) (xaiv δ = 25 phaj) | Rz(um)=70+1.2a Roughness 12.5 |

| 17 | Perpendicularity thiab nqes hav kam rau ua | μ(mm) = 0.4 + 0.015a Tool: Lub kaum ntse ntse |

| 18 | Lub kaum sab xis | Diagonal yuam kev ≦ ± 0.2 hli |

| 19 | Kev taug kev tsis sib xws | longitudinal ≦ ± 0.2mm / ntev ntev Horizontal ≦ ± 0.2mm / ntev ntev

|

| 20 | Torch lub kaum sab xis yuam kev | ≦ ± 0.5º |

| 21 | Cov khoom siv suab nrov | ≤80decibel |

| 22 | Pob loj | 4300x1900x1700 14CBM 1700KGS Ntoo rooj plaub los yog 20 feet thawv |

6. cnc plasma txiav tshuab nqe yog tsim nyog vim MainYam khoomyog cov npe nrov tshaj plaws

| Tsis muaj. | Lub npe | Hom | Keeb kwm | Yooj yim ua haujlwm |

| 1 | CNCTus tswj | Shanghai Jiaotong University F2300 | Tuam Tshoj | Nws muaj cov haujlwm ua tiav thiab kev ua haujlwm ruaj khov, uas tuaj yeem them nyiaj rau kev ua haujlwm ib feem rau slitting. |

| 2 | Tsis siv neeg programming nesting software | Starcam | Asmeskas | Kev them nyiaj yug, plasma bridging, nplaim co-ntug nruam txiav, ntse ces kaum ua, CAD txheej txiav, ntawv annotation, thiab lwm yam. |

| 3 | Servo tsav / lub cev muaj zog | Panasonic | Nyiv | Tswj ceev ceev, torque ceev yam ntxwv yog ib qho nyuaj heev, yooj yim txoj cai, yooj yim rau siv, |

| 4 | Reducer | NewtPib | Tuam Tshoj | Kev ntseeg siab, cov ntaub ntawv ua haujlwm siab, cov qauv compact, lub teeb yuag |

| 5 | Electromagnetic valve | AirTAC | Taiwan ua | Kub kub kuj, stability, zoo sealing |

| 6 | Kab | Shanghai Cardiff | Tuam Tshoj | Lub neej ua haujlwm ntev, muaj zog tiv thaiv kev cuam tshuam |

| 7 | Hluav taws xob hloov thiab relays | Schneider | Fabkis | Kev ua haujlwm ruaj khov |

| 8 | Hose | Sanshan | Kauslim | Kev kub siab ua haujlwm, kev ua haujlwm ntev |

| 9 | THC | Hong Yuda | Tuam Tshoj | Kev tswj xyuas siab, kev ua haujlwm ruaj khov, muaj peev xwm tiv thaiv kev cuam tshuam |

| 10 | Txiav taws lifting ntaus ntawv | YOG | Tuam Tshoj | Lifting motor, txhuas ntsia hlau, ob chav cylindrical linear zawv zawg qhia |

| 11 | CNC ncej | YOG | Tuam Tshoj | Steel box welded hnyav gantry qauv |

| 12 | Hwj chimqhov chaw | Raws li Rau koj xav tau | Tuam Tshoj | Lub txiav ceev yog ceev heev thiab cov nyhuv txiav yog zoo heev |

cnc ntshav tej tshuab nqe Daim ntawv teev cov cuab yeej random

| Tsis muaj. | Lub npe specification | Tus lej | Chav tsev |

| 1 | M4 rau lub kaum ntse ntse | 1 | teeb |

| 2 | M5 rau lub kaum ntse ntse | 1 | teeb |

| 3 | M6 rau lub kaum ntse ntse | 1 | teeb |

| 4 | M8 rau lub kaum ntse ntse | 1 | teeb |

| 5 | M10 rau lub kaum ntse ntse | 1 | teeb |

| 6 | M16 rau lub kaum ntse ntse | 1 | teeb |

| 7 | 6 "ib tug ntsia hlau ntsia hlau | 1 | teeb |

| 8 | 6 "kaum" screwdriver | 1 | teeb |

| 9 | Adjustable ciaj ntswj | 1 | teeb |

| 10 | Koob | 1 | teeb |

15.cnc ntshav txiav tshuab nqe yog kev sib twProject Case

16. Txiav qauv

17.cnc plasma tej tshuab nqe suav nrog zooKev pab cuam tom qab muag

(1) Tom qab kuaj thiab lees txais los ntawm cov neeg siv khoom, lub sijhawm lav yog 1 xyoos.

(2) Thaum lub sij hawm 1 xyoo lav, Yomi muab kev pab kho dawb yog tias tsis ua hauj lwm vim muaj qhov tsis xws luag / cov khoom, thiab hloov cov khoom puas / cov khoom tsis raug them nqi.Cov nqi thauj mus los yog nqa los ntawm cov neeg siv khoom, xws li cov nqi nthuav tawm.

(3) Thaum lub sijhawm lav 1 xyoos, thaum peb tau txais kev saib xyuas, peb yuav teb tsis pub dhau 8 teev, thiab teeb tsa 1: 1 pawg sib tham ntawm WhatsAPP lossis QQ txhawm rau taug qab, los ntawm video thiabcomputer chaw taws teeb tswj thiab lwm yam, coj tus neeg siv khoom kom tshem tawm qhov txhaum lossis hloov khoom siv.

If cov neeg xav tau kev kho ntawm qhov chaw, Yomi yuav npaj tus kws ua haujlwm txawv teb chaws (feem ntau yog 1 tus neeg, tuaj yeem hais lus Askiv) tam sim ntawd, tus nqi ntawm daim pib dav hlau (mus ncig), zaub mov, kev pab, kev thauj mus los hauv zos, kev txhais lus, internet, kev sib txuas lus thiab nqi vixaj rau peb cov engineers ntawm tus neeg yuav khoom qhov chaw yuav tsum tau txais los ntawm cov neeg siv khoom ntawm qhov tseeb tawm tsam cov ntaub ntawv pov thawj.

Cov nyiaj pub dawb mus ncig USD 100 / ib tus neeg hauv ib hnub rau yim (8) teev rau kev taug kev los ntawm Tuam Tshoj mus rau cov neeg siv khoom hauv zos qhov project thiab xa rov qab yuav tsum raug txiav txim siab ntxiv ntawm qhov tseeb.

(4) Tom qab lub sijhawm lav, cov khoom hloov pauv yuav raug them nqi ntawm tus nqi thauj mus los. Cov nqi thauj mus los yog cov neeg siv khoom, xws li cov nqi xa tawm / nqi cua.

(5) Tswj system thiab software yuav hloov kho lub neej dawb.

(6) Tsuas yog tib neeg kev puas tsuaj rau lub tshuab, Yomi muab kev pab cuam lub neej ntev.